Principle / Thermal Actuators

Thermal actuator is also called thermal wax element, wax element, thermostatic element. The thermal actuator can convert heat energy into mechanical energy, and has the function of rapidly and automatically transmitting mechanical action after induction of temperature changes. Its mechanical action is derived from thermal expansion material. Thermal actuator is not affected by the surrounding environment. It is the key component of various temperature regulation and control systems. It has the advantages of wide temperature adjustment range, accurate temperature control, simple structure, reliable performance and so on. Thermal actuator is widely used in automotive industry, building heating, sanitary bathing, HVAC, solar water heater, petrochemical, shipbuilding, industrial automatic control, fire extinguishing, household appliances, safety devices, aerospace and other fields.

In line with internal sealing methods of thermostatic element, thermal actuator can be divided into squeeze-push type, diaphragm type and piston type.

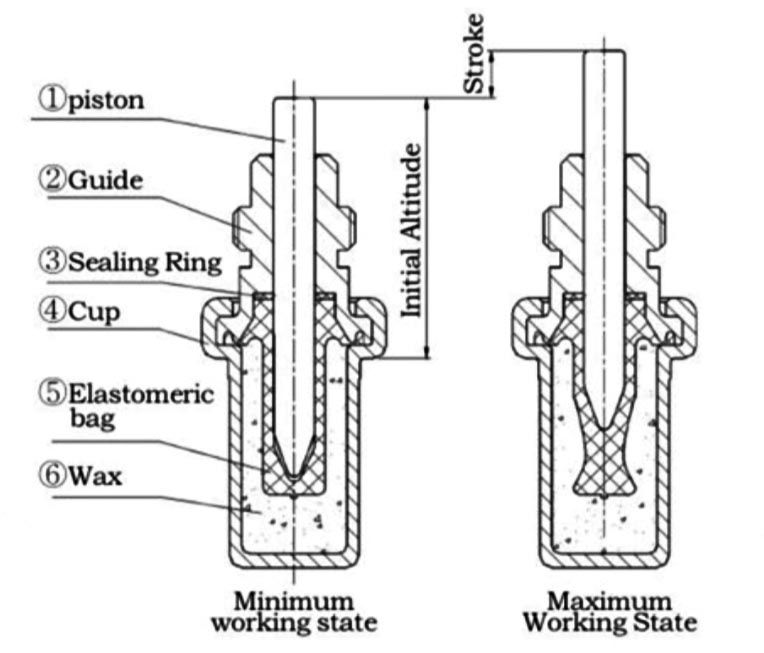

1. Squeeze-push Type

Working Principles

A sealed capsule is composed of guide②, cup④, elastomeric bag⑤. Wax⑥ is sealed in the cup④ while piston① is surrounded in the elastomeric bag⑤. When the temperature of medium outside cup④ rises and over the minimum working temperature of thermostatic element, wax⑥ expands and the pressure applies, via the bag, both a radial force (squeeze) and an axial force(push) on the piston① to makes movement. Again, an external spring ensures the return of piston when the temperature decreases.

Structural Features

Advantages: Larger stroke distance, higher reliability, the preferred choice for engine thermal management system.

Weakness: Worse than diaphragm type in sensitivity and hysteresis.

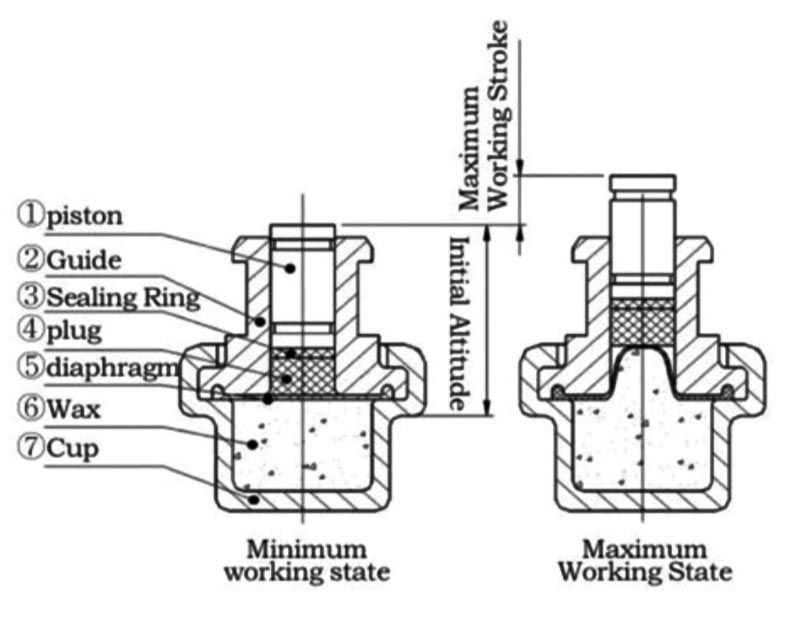

2. Diaphragm Type

Working Principles

A sealed capsule is composed of guide②, cup⑦, diaphragm. wax⑥ is sealed in the cup⑦. When the temperature of medium outside cup⑦ rises and over the minimum working temperature of thermostatic element, wax⑥ expands and pushes against the diaphragm⑤ the movement is transmitted via the plug④ to the piston①. The guide② maintains the diaphragm, and allows the plug and piston to slide freely. An external spring ensure the return of the piston when cooling down.

Structural Features

Advantages: Precise movement path, high sensitivity, the preferred choice for sanitary applications and heating system.

Weakness: Worse than squeeze-push type in reliability, not suitable for the large- stroke product (over 10mm).

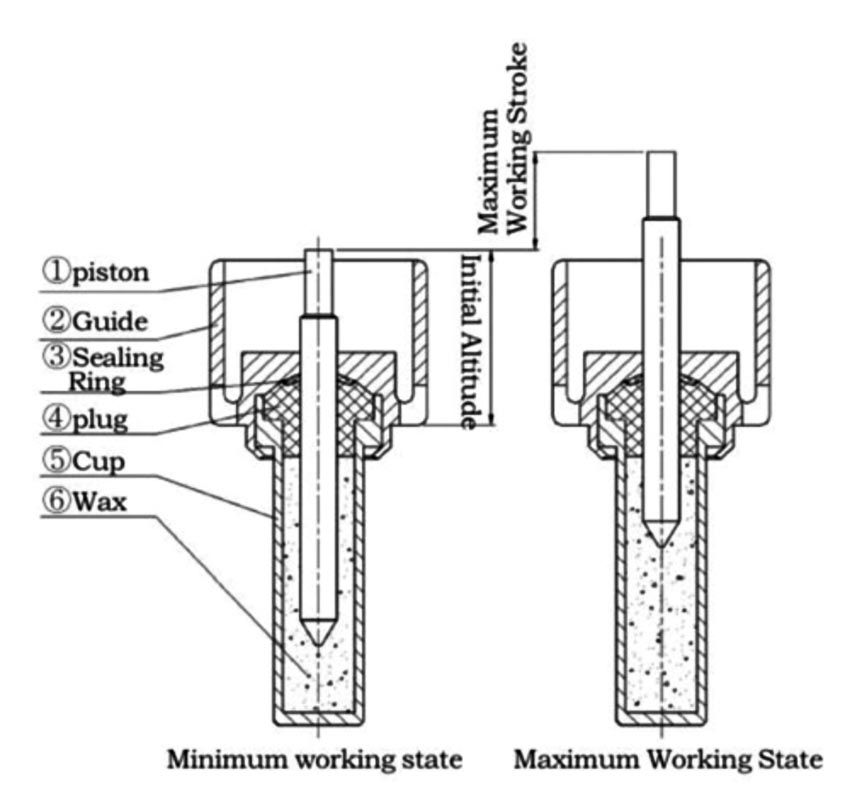

3. Plunger Piston Type

Working Principles

A sealed capsule is composed of guide②, cup⑤, rubber plug④. Wax⑥ is sealed in the cup⑤. When the temperature of medium outside cup⑤ rises and over the minimum working temperature of thermostatic element, wax expands and pushes against the piston movement Again, an external ensure the return of the piston when the temperature decreases.

Structural Features

Advantages: Large stroke, big absorbing load, small volume, generally used in engine cooling system or some other special application.

Weakness: Worse than squeeze-push type in reliability, poor hysteresis.

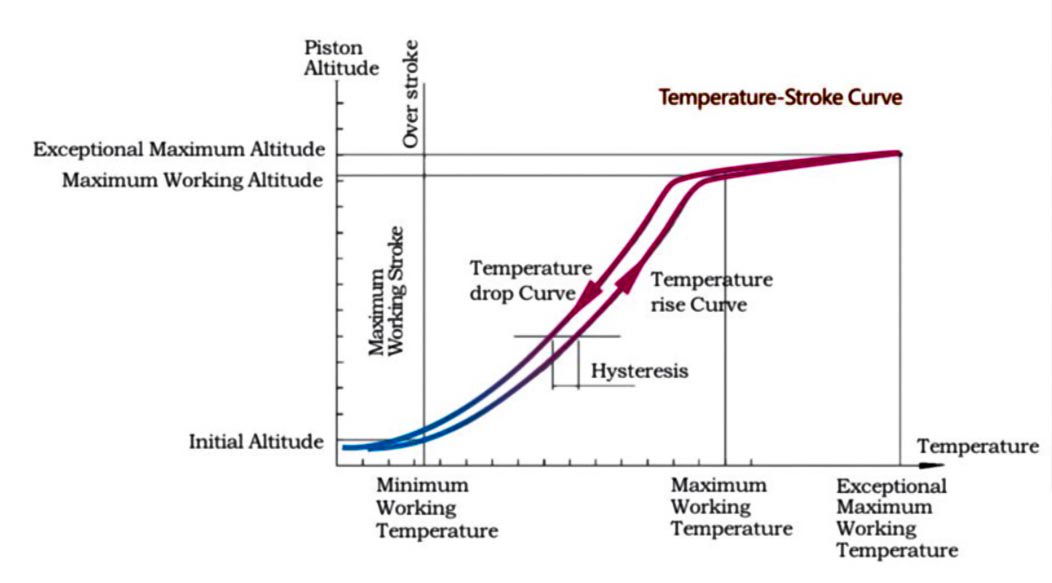

Terminology of Thermal Actuator

Initial Altitude: The initial altitude of the piston measured from a reference level when it is static.

Full opened Stroke: The displacement of piston from initial altitude under the full opened temperature.

Overstroke: The displacement of piston from initial altitude under utmost working temperature.

Hysteresis: The disparity between the temperature rise curve and temperature drop cooling curve of thermostatic elements, which is decided by the composition of wax.

Sensitivity: The time when the top of piston up to the full opened stroke under certain temperature.